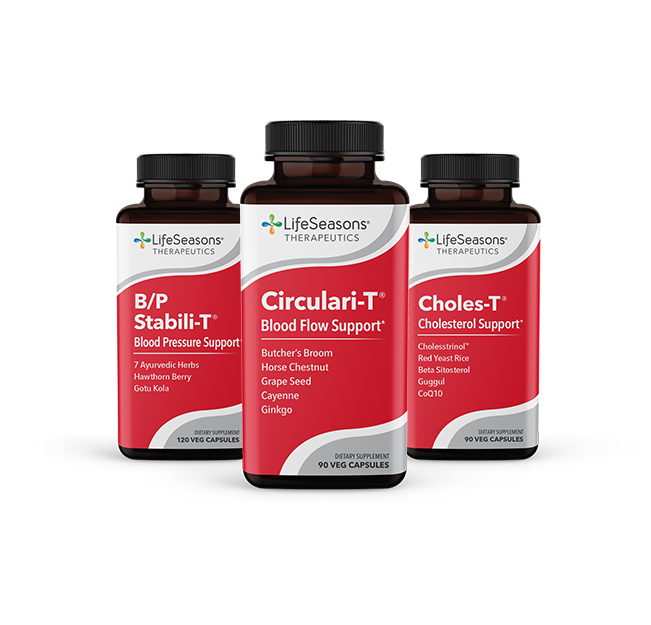

LifeSeasons’ Manufacturing Facilities

All of our products at LifeSeasons are manufactured in a GMP facility (Good Manufacturing Practice facility). This means the FDA ensures that we use the Good Manufacturing Process to create only quality products for consumers.

Our facility is also an FDA food grade facility. With these facility certifications we could manufacture OTCs as it has met that quality standard.

How We Test Our Ingredients

We test all incoming ingredients for identity, microbial, heavy metals, and for potency. Each ingredient is tested three times:

- when raw ingredients are received,

- during the manufacturing process,

- and the finished product.

At LifeSeasons we have one of three botanists in the United States with the ability to test ingredients the way we do. Every single incoming raw ingredient is inspected by our botany team. Through a microscope, each ingredient is examined to identify the active constituent and pictures are recorded for our records. Any ingredients found with any adulterants or does not achieve our high quality standards is rejected and the shipment is sent back.

They also looks for adulterants, as mentioned above. Most things that are adulterated are usually vitamins and minerals, not herbs.

LifeSeasons’ Testing Process

| Incoming Raw Material: Botanicals | Incoming Raw Material: Botanical Extracts |

|---|---|

|

|

| Incoming Raw Material: Chemicals | Finished Products |

|

|

| * Statistical Sampling Plan (SSP) is implemented after the first 3 batches have been tested; it is implemented for logical increments, depending on the raw ingredient or product.

** Microbial testing consists of TPC (Total Plate Count), E-coli, Coliforms, Yeast & Mold, Staphylococcus, and Salmonella. |

|

INGREDIENT STANDARDS

Our Ingredient Standards at LifeSeasons

We take great pride and care in how we select, source and test our ingredients for each of our supplements. We conduct extensive research on individual ingredients and develop formulas that work synergistically to deliver maximum potency. We are always on a quest to identify the best ingredients to help you maintain an optimum state of health.

How We Select Our Ingredients

Each of our supplement products are thoughtfully crafted. When we begin working on a new supplement, we make sure that we select ingredients that are at a clinically studied level. This ensures that they have a physiological impact on your body and that they are efficacious and successful in producing a desired or intended result.

With new formulas, we begin by talking about a health condition. LifeSeasons VP of Product Development then leads our product development team, with over 150 years of combined experience in the natural product industry, including a biochemist and master herbalist.

Through a collaborative approach, they look at key ingredients we want to use, why the ingredients are chosen, what studies have been done on each ingredient, and where the ingredients have proven to be helpful in showing results.

Once we have identified our unique, synergistic formula and our biochemist has designed it, we then source our ingredients. We work with suppliers we have trusted relationships with and have worked with on other supplement products and begin sourcing the ingredients needed.

How We Source Our Ingredients

We source ingredients for each of our supplements at LifeSeasons from all over the world. Some of the ingredients we source are called branded ingredients due to either a patented process or having patented intellectual property regarding specific research and/or clinical trials for a given function.

When our product development team deems it more beneficial for the functionality of the formula, or more beneficial for the end result, to include branded ingredients on certain raw materials then we follow suit.

Some of the branded ingredients we source include Sensoril, Mirtoselect, BenfoPure, and Cholesstrinol HP.

Ingredient integrity is of paramount importance for LifeSeasons to assure we provide you with well crafted formulas to support you in your health journey.

LifeSeasons Botanist

LifeSeasons’ Testing Process

Further Ingredient Testing

We have also gone back ourselves and pulled our product off store shelves one year later or close to expiration date to test potency.

We did this with our Digestivi-T product which has a one-year expiration date. One of the ingredients in Digestivi-T is a probiotic which can be active. When this ingredient is active due to temperature or moisture, it ends up losing their efficacy.

Although we use a shelf stable probiotic in our products, we still pulled the product off a store shelf at about the time of expiration to test. This allowed the product to go through its normal process of being shipped and shelved.

We then tested it to ensure that when people are buying that product, even close to the expiration date, that what we state on the supplement facts is what you get, even when it gets close to the expiration date.

What happens if an ingredient doesn’t pass testing?

If an ingredient at our manufacturing facility fails to pass any one of our tests, we reject the entire batch. We have lost business and been out of stock on products due to rejection of ingredients coming in that are not at our standards. We have done this in the past and are willing to do it in the future at the cost of ourselves.

Best Ingredients, Best Formulas, Best Results

At LifeSeasons we live by the saying: Best ingredients, best formulas, best results. We believe that getting the best ingredients will make the best formulas, and ultimately, you’re going to get the best results.

Certifications

GMP – Good Manufacturing Practice

Dietary Supplements GMP Registration. Good Manufacturing Practices (GMPs) are guidelines that provide a system of processes, procedures and documentation to assure a product has the identity, strength, composition, quality and purity that appear on its label.

Our manufacturing facility and our product labels are in full compliance of this standard.

Learn more at https://www.fda.gov

Gluten Free

Our gluten testing program ensures our products are gluten free. Each product is tested to be free of gluten at <10 ppm. This requirement is stricter than the legal FDA definition for gluten-free of <20 ppm.

Learn more at https://www.fda.gov

NSF International

The NSF International certification mark on a product means that the product complies with all standard requirements. NSF conducts periodic unannounced inspections and product testing to verify that the product continues to comply with the standard. The mark also provides knowledge that an impartial review against established criteria or guidelines has been conducted, evidence that product labeling and claims have been objectively reviewed by a trusted third party, evidence of the organization’s company-wide commitment to quality, compliance and safety.

Our manufacturing facility is NSF International certified, and we are in-process of obtaining individual certifications for each of our products.

Learn more at http://www.nsf.org/